The Importance of Foam Protective Packaging

Introduction to Foam Protective Packaging

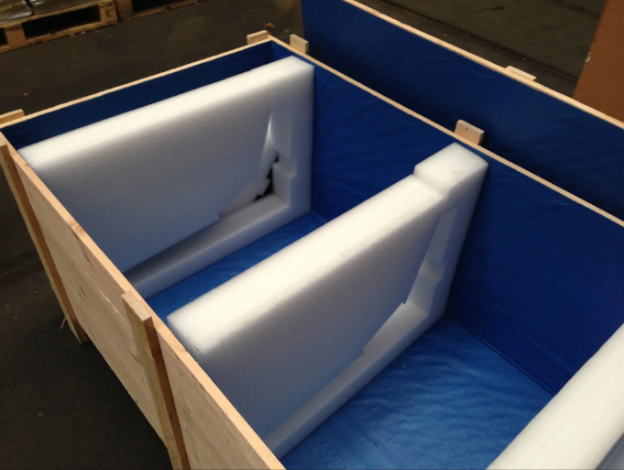

Foam protective packaging is an essential solution for businesses looking to safeguard their products during transit and storage. Designed to absorb shocks, vibrations, and external impacts, this type of packaging ensures that delicate and valuable goods reach their destination in pristine condition. Whether used in electronics, automotive, healthcare, or industrial applications, foam protective packaging provides unmatched security, making it a preferred choice for manufacturers and suppliers worldwide.

Understanding Polyethylene Foam Protective Packaging

Polyethylene foam protective packaging is one of the most reliable and versatile packaging solutions available today. It is made from polyethylene, a durable and lightweight polymer known for its excellent cushioning properties. This foam is widely used in multiple industries due to its ability to absorb and distribute impact forces efficiently.

Key Features of Polyethylene Foam Packaging

- Shock Absorption – The cellular structure of polyethylene foam acts as tiny shock absorbers, reducing damage caused by external forces.

- Durability – Unlike other packaging materials, polyethylene foam maintains its structure even after multiple impacts, making it suitable for reusable packaging.

- Moisture and Chemical Resistance – It protects products from moisture, chemicals, and temperature fluctuations, ensuring their longevity.

- Customization – Available in various colors, including black, white, blue, and anti-static pink, polyethylene foam can be tailored to meet specific packaging requirements.

- Multi-Trip Usability – It is commonly used for returnable transit packaging, ensuring that expensive products remain undamaged throughout their journey.

Why Choose Polyethylene Packaging?

Polyethylene packaging offers several advantages over conventional packaging materials like polystyrene. It is more robust, sustainable, and suitable for high-value products. Companies looking for long-term protection often opt for polyethylene foam protective packaging due to its cost-effectiveness and high performance.

Applications of Polyethylene Foam Protective Packaging

- Electronics: Protects delicate devices like smartphones, laptops, and circuit boards.

- Automotive: Used for securing vehicle components during shipping.

- Healthcare: Ensures medical equipment remains safe and sterile.

- Industrial Use: Provides heavy-duty protection for machinery and tools.

- Furniture: Acts as cushioning to prevent dents and scratches.

Custom Foam Protective Packaging

Custom foam packaging is a game-changer for businesses looking to create tailored solutions that enhance their brand image and product safety. At Advanced PP, we specialize in designing and manufacturing bespoke foam protective packaging to meet unique industry demands.

Benefits of Custom Foam Packaging

- Enhanced Protection – Custom foam packaging is designed to fit products perfectly, minimizing movement and preventing damage.

- Brand Enhancement – Businesses can use custom shapes and colors to create a visually appealing packaging experience.

- Cost Efficiency – Properly designed foam packaging reduces material waste and improves shipping efficiency.

- Versatile Material Options – Different types of foam, including polyethylene, polyurethane, and polystyrene, can be used to achieve desired protection levels.

Versatile and Innovative Packaging Solutions

At Advanced PP, we provide a complete range of foam protective packaging solutions, ensuring that our customers receive the best protection for their products. Our packaging solutions include:

1. Bespoke Foam Packaging

We create custom-designed foam fitments to secure fragile and sensitive products. From industrial components to retail packaging, our solutions are tailored to ensure maximum safety.

2. Multi-Purpose Foam Applications

Our foam packaging solutions are suitable for various industries, including:

- Electronics: Shock-absorbent foam inserts for delicate components.

- Furniture: Cushioned layers to prevent surface damage.

- Toolkits: Organized foam inserts for easy access and protection.

3. Sustainable Packaging Options

As an environmentally conscious company, we prioritize the use of reusable materials like polyethylene, which can be used multiple times without degradation. This reduces waste and promotes sustainable business practices.

Why Work with Advanced PP?

1. Expert Craftsmanship

With years of experience in foam protective packaging, we deliver top-tier products crafted to the highest standards.

2. Cutting-Edge Technology

We use advanced manufacturing processes to create intricate and precise foam designs that provide a secure fit for products.

3. Fast Turnaround & Reliable Delivery

Based in Manchester, we offer quick and efficient delivery services across the region and beyond.

4. Competitive Pricing

We provide cost-effective packaging solutions without compromising on quality, ensuring businesses get the best value for their investment.

Read also: Acoustic Foam Soundproofing: Enhancing Noise Control

Conclusion

Foam protective packaging is an essential investment for businesses looking to ensure the safety of their products. With options like polyethylene foam, custom packaging, and multi-purpose applications, companies can enhance protection, reduce costs, and improve their brand image. Advanced PP offers high-quality, bespoke solutions tailored to individual business needs.